"The Meat Institute’s first-ever continuous improvement report is a game changer for transparency in the sector – setting transparent baselines that will allow us to measure progress and verify our sector’s contributions to global goals,” said NAMI President and CEO Julie Anna Potts. Potts was referring to the first of many reports to come from the North American Meat Institute’s (NAMI) Protein PACT (for the People, Animals, and Climate of Tomorrow).

Recent posts by Kathy Barbeire

2 min read

CAT Squared Supports NAMI Protein PACT with Meaningful KPI Data

By Kathy Barbeire on Apr 10, 2023 6:36:20 PM

Topics: meat industry poultry industry continuous improvement multi-site benchmarking

1 min read

IPPE TECHTalk Examines a Business’s Readiness for Smart Automation

By Kathy Barbeire on Jan 8, 2023 8:59:10 PM

Join CAT Squared's Jack Teague for his IPPE TECHTalk presentation Assessing a Business's Readiness for Smart Automation and Winning Stakeholder Support. The presentation will feature three main objectives:

Topics: continuous improvement food manufacturing automation food manufacturing AI gaining support for technology projects industrial internet of things digitized plant floor industry 4.0

3 min read

Important Dates and Details for FSMA Traceability Requirements

By Kathy Barbeire on Dec 26, 2022 11:55:35 PM

New FDA traceability requirements are effective January 20, 2023. The FSMA Final Rule: Requirements for Additional Traceability Records for Certain Foods includes a requirement for those who manufacture, process, pack, or hold foods on the Food Traceability List (FTL) to establish and maintain records containing Key Data Elements (KDEs) associated with different Critical Tracking Events (CTEs). The FDA notes that while the proposed requirements only apply to those foods on the FTL, “they were designed to be suitable for all FDA-regulated food products. FDA would encourage the voluntary adoption of these practices industrywide.”

Topics: Era Smarter Food Safety Traceability technology food traceability Labeling key data elements critical tracking events GS1 Standards

1 min read

Join us at the CYNERGY Pavilion at IPPE in Hall C-12825

By Kathy Barbeire on Dec 13, 2022 4:06:18 PM

Topics: mes software food manufacturing software continuous improvement software manufacturing operations management software ctb food supplychain solutions improving manufacturing performance digitized plant floor

3 min read

The First 5 Steps to Digitize Your Plant-Floor

By Kathy Barbeire on Nov 29, 2022 11:55:25 PM

If you’re a protein processor that has yet to take a significant step into the world of Industry 4.0, you're not alone. Globally, 90 percent of manufacturing companies are Digital Novices, Followers, or Innovators, and less than one-third are well-advanced on their digital journey. If you are just starting out, here are five practical steps to help meat and poultry processors improve manufacturing performance by digitizing their plant floor operations with Industry 4.0 technology.

Topics: manufacturing automation technology adoption manufacturing technology plant-floor software production optimization industrial internet of things improving manufacturing performance digitized plant floor industry 4.0

1 min read

User Summit Early-Bird Pricing Ends March 15

By Kathy Barbeire on Mar 14, 2022 11:54:17 AM

Last Chance to save $100 off the Registration Price

The theme of this year's User Summit is Accelerating Continuous Improvement by Applying Industry 4.0 to Protein Production. CAT Squared along with our CTB sister companies are building a fully integrated platform that enables smart-manufacturing concepts such as the application of AI and machine learning to manufacturing processes. Several keynote presentations will demonstrate how these Industry 4.0 principles are being applied to meat and poultry processing.

Topics: News continuous improvement manufacturing software process alignment ctb food supplychain solutions improving manufacturing performance CAT Squared User Summit

3 min read

5 Reasons Why Meat & Poultry Processors Should Attend the User Summit

By Kathy Barbeire on Mar 8, 2022 11:07:51 PM

The CAT Squared User Summit is designed to add value to food production operations by sharing best practices in the industry for adopting new technology in manufacturing processes. This year's Summit will be hosted at the Winthrop Rockefeller Institute atop Petit Jean Mountain. The Institute provides an inspiring, secluded, historic setting to learn, connect, and innovate. This year's theme is Accelerating Continuous Improvement by Applying Industry 4.0 to Protein Production. Here are the top five reasons meat and poultry processors should attend the User Summit:

Topics: poultry industry News Arkansas Business manufacturing software process alignment production optimization overcoming end-user resistance successful mes implementation improving manufacturing performance

1 min read

CAT Squared Named Finalist for Arkansas Business of the Year

By Kathy Barbeire on Dec 29, 2021 4:28:47 PM

CAT Squared has been named a finalist for the 34th Annual Arkansas Business of the Year Awards, which recognizes the state’s top businesses, nonprofits, and executives.

Topics: News Arkansas Business Arkansas Business Expansion cat squared news

2 min read

CAT Squared Team Member Publishes Study on Foodborne Pathogens

By Kathy Barbeire on Sep 14, 2021 3:53:21 PM

The August 2021 Journal of Food Protection featured a research article from CAT Squared Implementation Specialist Sheridan Brewer.

Brewer was part of a research team from the University of Georgia that investigated the viability of foodborne pathogens and changing microbial community dynamics in the popular fermented beverage, kombucha. Results were collected using four different home kombucha-brewing kits over at least two 14-day trials of fermentation period for each kit brand. The different microbiota groups, including Lactobacillus spp., which are often recognized as the probiotic cultures in kombucha, surmounted a large population by the third day of fermentation and stabilized after that. The foodborne pathogens studied – Salmonella spp. and Escherichia coli – were, surprisingly, able to survive in small numbers ( < 10 -100 CFUs/mL) to the end of a 14-day fermentation period in some kits. However, on average, both pathogens demonstrated a 5-log reduction or greater in population numbers by day 10 of the fermentation period. A 5-log reduction (death of 100,000+ cells/mL) of pathogens is the same standard applied to juice products in HACCP guidance from the U.S. FDA, which could be considered a reasonable standard to apply to this same raw, unpasteurized product.

Overall, researchers determined the indigenous microbiota (“probiotics”) in the beverage did not play a strong role in influencing the survival of any pathogens, but instead, survival was strongly influenced by changes in pH (increase in acidity). The type of base tea used to brew kombucha did play a significant role in the survival of pathogens; kombucha brewed from an oolong/black tea mix demonstrated the most rapid reduction in pathogens as opposed to kombucha brewed with green tea. Lastly, strict hygienic practices were recommended for the preparation of the fermented beverage because the combination of sugar content, water activity level, and gradual change in pH in kombucha fermentation were able to provide a perfect storm for the development and survival of some acid-resistant pathogens.

"CAT Squared wants to congratulate Sheridan on his great accomplishment," said CAT Squared CEO Vernon Smith. "We're proud to have such a driven, talented mind on our team."

Topics: foodborne pathogens food safety journal of food protection

2 min read

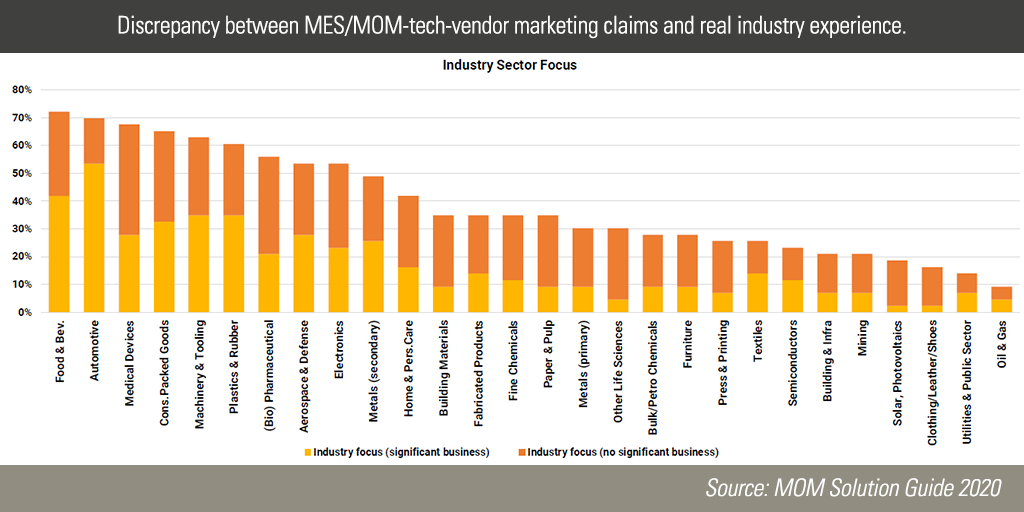

Supporting Manufacturing Automation Goals by Aligning MOM Technology

By Kathy Barbeire on Jan 25, 2021 5:17:43 PM

The 2020 pandemic has accelerated the adoption of Industry 4.0 technologies among manufacturers. In the wake of lockdowns and social distancing measures, manufacturers are vulnerable to their dependence on manual labor, and this vulnerability is driving them to look at automation. The Manufacturing Operations Management Institute (MOMi) has released the MOM Solution Guide 2020 as a resource for manufacturers looking for technology vendors with solutions aligned to their industry. The 475-page Guide tracks trends in the MES/MOM industry (Manufacturing Execution Systems / Manufacturing Operations Management). This year, the report included feedback from MES suppliers from around the world who submitted data on 43 MES products, their services, technologies, quality, and industry focus.