Real-Time Data

Access to real-time, actionable data facilitates informed, proactive decision-making.

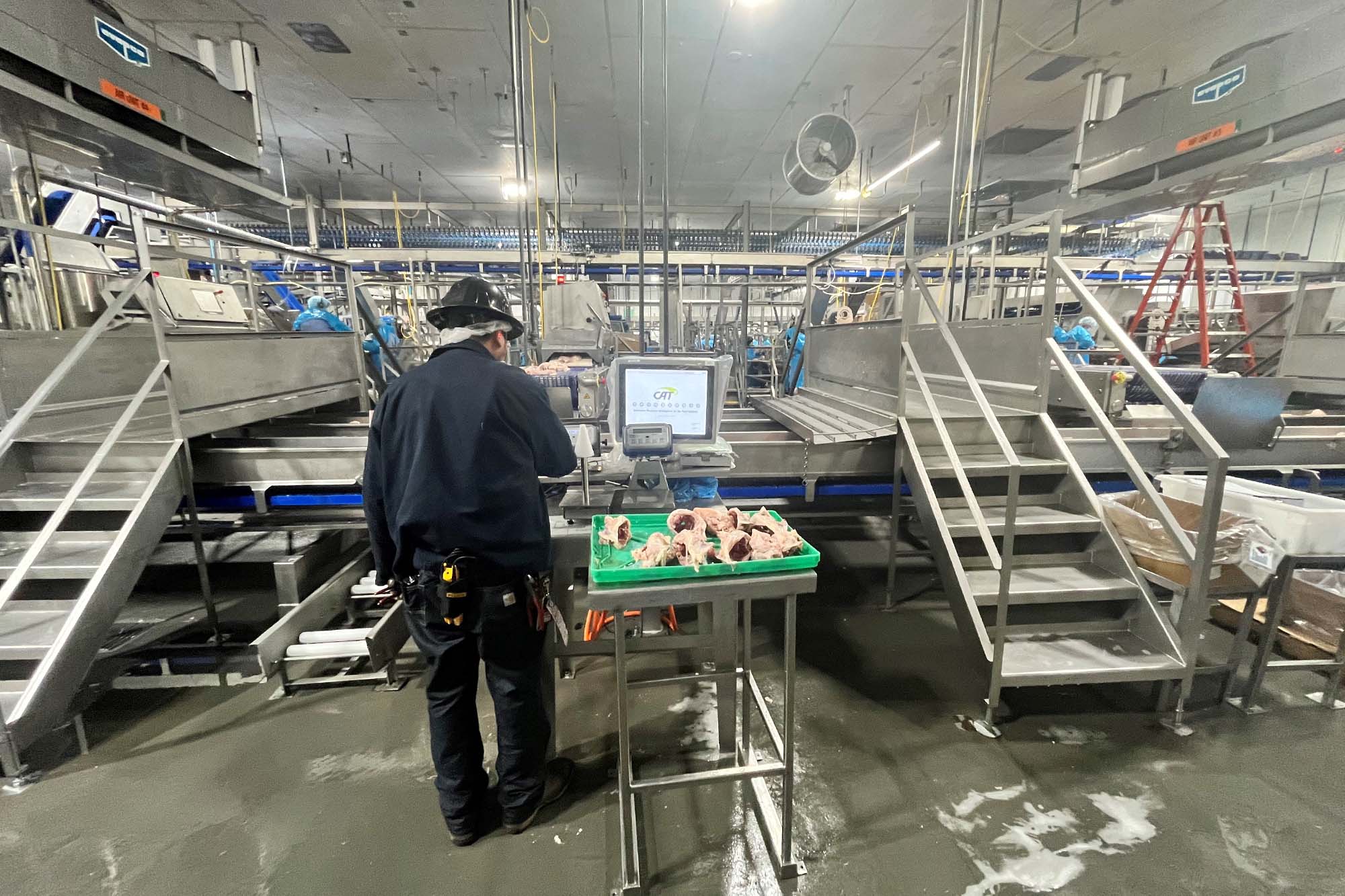

Manages processes from receiving live animals through printing bills of lading.

Monitors and controls value-added processes including cooking, cooling, and batch mixing.

Controls inventory while maintaining full traceability of dry goods, products, and ingredients.

Paperless data collection and reporting for quality control, sample management, and continuous improvement.

Drives continuous improvement with real-time process visibility displayed on customizable executive dashboards or plant-floor scoreboards and OEE reporting

Improves OEE, increases uptime, reduces scheduled downtime, and automatically creates and assigns work orders based on anomaly detection.

Maximizes profit through optimized production schedules, highlighting bottlenecks and surpluses.

Multi-step forward and backward recall powered by cloud-based technology.

Enables seamless connectivity across diverse systems, ensuring our solution remains both hardware- and software-agnostic.

Where we deliver:

Access to real-time, actionable data facilitates informed, proactive decision-making.

Through improvements to yields and efficiencies, most of our customers report a real ROI of 3-6 months.

Standardization of business processes simplifying benchmarking across multiple locations.

Normalization of plant data and integration capabilities simplifies ERP deployment and eliminates the need for customization in the ERP to cater to variances in shop-floor data collection.