The 2020 pandemic has accelerated the adoption of Industry 4.0 technologies among manufacturers. In the wake of lockdowns and social distancing measures, manufacturers are vulnerable to their dependence on manual labor, and this vulnerability is driving them to look at automation. The Manufacturing Operations Management Institute (MOMi) has released the MOM Solution Guide 2020 as a resource for manufacturers looking for technology vendors with solutions aligned to their industry. The 475-page Guide tracks trends in the MES/MOM industry (Manufacturing Execution Systems / Manufacturing Operations Management). This year, the report included feedback from MES suppliers from around the world who submitted data on 43 MES products, their services, technologies, quality, and industry focus.

“The Solution Guide aims to provide our clients and business partners with clear solution overviews and insights into market developments,” said Jan Snoeij, president/senior consultant at the MOM Institute. “Each MES supplier was asked to complete a survey of over 300 questions about their products, implementation process, technology stack, industry focus, and more.”

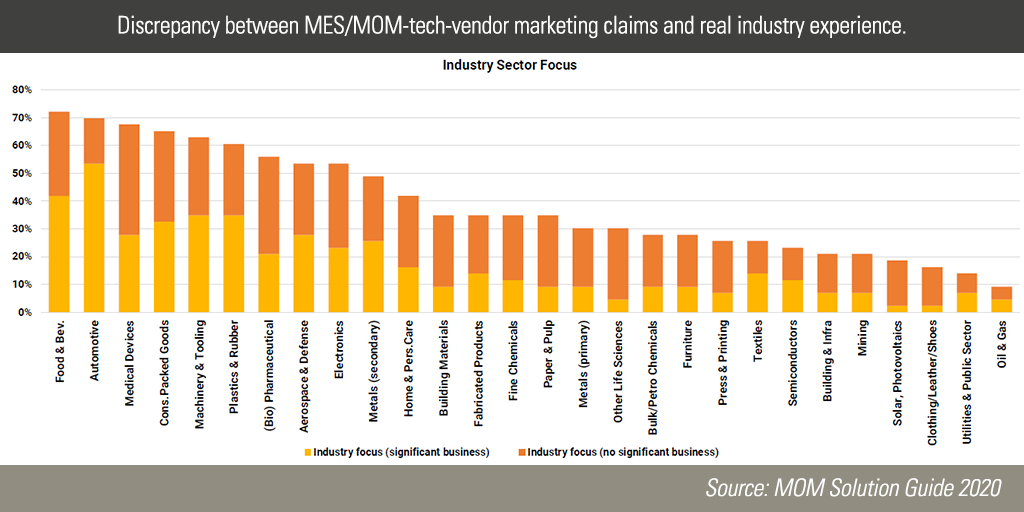

Among the more interesting findings of the survey was the amount of discrepancy between marketing claims and real industry focus. Referring to the chart above, 72% of survey responders claimed their system was relevant to the food & beverage industry. However, only about 40% of respondents have done significant business in that industry. (“Significant business” was defined as having at least 5% of your total business coming from that sector.)

This discrepancy should caution manufacturers to verify the claims of vendors as they search for the right solution to automate their processes. Additionally, there are variations within sectors that also need to be considered. A recent implementation at Lake Foods, a poultry facility in Georgia, is a good example.

“The MES we were working with was specifically focused on Food & Bev (it was 100% of their business), but they did not have much poultry experience,” said Mary Beth Strawn, CFO of Lake Foods. “The one-to-many process was newer to them. I spoke to multiple protein referrals before committing, but I didn’t realize how specialized poultry was compared to other protein businesses. I may have ultimately been able to configure the MES for our business, but then layering in the complexity of the ERP integration pushed me over the edge. I don’t have time to design two systems to work together and both sides (MES & ERP) were not willing to help with what seemed to them a ‘specialized request.'”

As Lake Foods’ experience illustrates, even if considering a vendor with experience in your industry, it’s still important to look at their implementation history and see if their experience matches your process. The disassembly process in primary facilities is completely different from the mixing processes in further-processing facilities. The MES system must be aligned with those processes in order to seamlessly integrate into your plant floor.

Industry-fit is only one area covered in the MOM Solution Guide 2020. The guide provides extensive information, primarily to manufacturers, to help them with their selection of an appropriate MOM solution to improve their performance.

CAT Squared is one of the 43 MES vendors that participated in the survey. You can access the report on the MOMi website to see how our capabilities stack up against our competitors. Of all participants, CAT Squared was the only MES vendor that ONLY focused on the food industry. We have extensive experience in primary and further-processing facilities. Feel free to review our customer list, read our case studies, or request a demo.